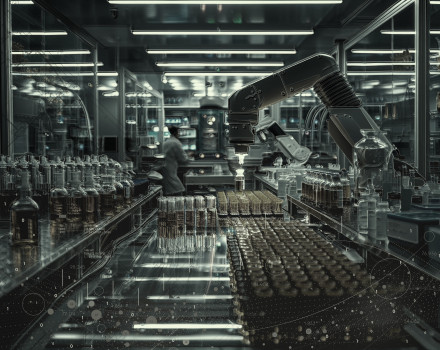

BakerHicks, the design, engineering and project delivery company, are delivering multi-disciplinary design services for a new advanced manufacturing facility to enable AstraZeneca to meet demand for their oncology medicine, Zoladex.

Officially announced following a site visit by UK Prime Minister, Boris Johnson, the new facility is part of a £380m manufacturing and packaging portfolio on AstraZeneca’s Macclesfield campus. The complex sterile production process for the Zoladex drug relies solely on the manufacturing capabilities and skilled workforce of the campus, which is the UK’s largest medicines development and manufacturing site.

BakerHicks were appointed to provide multi-disciplinary design services, including process engineering, architecture, civil and structural engineering, mechanical and electrical services, and controls and instrumentation services, for the detailed design phase of the project. They are also fulfilling the principal designer, safety study chair and BIM manager roles, delivering the project to BIM Level 2 and managing the common data environment.

The company have a long history of working with AstraZeneca, including having been involved in a number of earlier facilities for the manufacture of Zoladex. The design of the new facility is based on these pre-existing facilities but incorporates a range of improvements and new technological developments, including integrating a new filling and assembly line within the manufacturing facility and an enhanced fire resistant elevation.

Tom Dickinson, project director at BakerHicks, says the collaborative ethos on the project has been key to its success:

Our expertise in BIM and 3D design has really come to the fore throughout. For example, creating a 3D Point Cloud model meant that, despite not being able to be onsite as we would have been under normal circumstances, we had an exact reference point and were able to formulise the design with digital measurements.

Construction is now underway on the project, which is expected to complete end of 2022.