Q. What has changed?

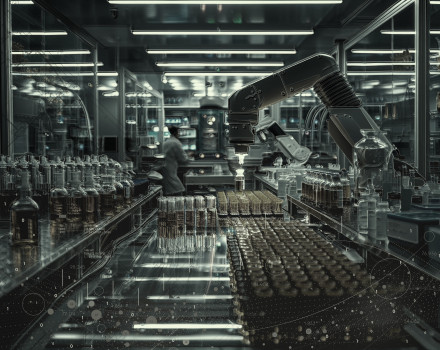

A. This latest version contains 59 pages of updated requirements for the manufacture of sterile medicinal products. An extensive review process has taken place since the last revision was issued in 2008, bringing the regulations into line with regulatory and manufacturing changes. Ultimately the aim is to reduce the frequency and severity of product recalls in the industry, which saves all parties time and money, and most importantly, protects the consumer.

The main updates are in the Pharmaceutical Quality Systems (PQS) section, including requirements for Quality Risk Management (QRM) and Contamination Control Strategy (CCS), both of which are increasingly vital to any controlled environment manufacturing process. Another notable change is the expansion in coverage for new technologies, for example isolators and restricted access barrier systems (RABS), which helps modernise the regulations and bring them in line with the latest developments. Requirements for monitoring, trending, disinfection, cleaning and training have also been expanded and updated in this latest version.

Q. What does this mean for manufacturers?

A. These new requirements will come into force in August 2023, so manufacturers still have time to prepare. Consultancies such as BakerHicks are able to help them identify where they need to make changes, help design compliant equipment that meets their needs and give guidance on the QRM and CCS systems needed to bring their operations in line with the new regulations.

When it comes to the QRM and CCS elements of these new regulations, it is intended that companies should use the tools described in the ICH Q9 and Q10 guidelines for quality risk management and pharmaceutical quality systems. This will help them understand the processes and what they need to implement to remain compliant. For CCS in particular, manufacturers need to assure that their process performance and product quality meets the defined parameters. This will help reduce the risk of contamination, and having a process and equipment designed to meet this will be essential.

Q. Do the changes apply to other manufacturers?

A. Whilst the Annex is aimed at sterile medicinal product manufacturers, it is not limited to medicinal products. Some of the principles within it should also be used to support the manufacture of other products not intended to be sterile, but which have a specified low bioburden, for example liquids, creams, ointments and low bioburden biological intermediates. Companies manufacturing these products should also be paying close attention to the changes and looking to assess their processes and equipment to ensure they fall within the parameters of the regulations.

Q. How can design help manufacturers ensure compliance?

A. The new QRM updates mean manufacturers will need to identify what measures they will need to take to meet process performance and product quality requirements. This requires a holistic evaluation of their facility’s infrastructure, such as the clean rooms, clean utilities and facility cleaning, as well as the production process, including their equipment’s design and how it is sterilised and cleaned, including a justified sampling plan.

Whether it if for an existing facility or a new build this is an extensive task and design and engineering companies such as BakerHicks are well placed to help. They have the experience across all design disciplines to perform a thorough and quality QRM, enabling them to define the most suitable design for a facility and production process that will ensure compliance with the new regulations. In addition to this, they are able to design in new, innovative solutions to the facility’s design and production process that will ensure product compliance. This offers manufacturers not only peace of mind that they are meeting all the regulatory requirements, but also provides long-term cost and time savings through designing the facility and processes to be as efficient as possible.