- Sector

- Client Morgan Sindall Infrastructure | National Grid | Network Rail

With electric rolling stock creating ever increasing service requirements and demands on the rail network, the Sundon 25kV DNO project is designed to provide the Midland Mainline Electrification with greater availability and load capacity.

Connecting a National Grid substation to a Network Rail auto transformer feeder station, powering the Midland Mainline Electrification

Future-proofing load capacity to deliver a more efficient rail service

Designs that minimised the health and safety risks of working alongside a live railway line, motorway and substation

With electric rolling stock creating ever increasing service requirements and demands on the rail network, the Sundon 25kV DNO project is designed to provide the Midland Mainline Electrification with greater availability and load capacity. It will see Network Rail’s new Auto Transformer Feeder Station (ATFS) connected to National Grid’s 400kV Substation at Sundon, thereby futureproofing the line’s power supply.

BakerHicks are providing structural engineering and cable system Front End Engineering and Design (FEED), detailed design and construction support services, as well as the production of as-built drawings, for the two new 25kV underground cable routes and associated equipment.

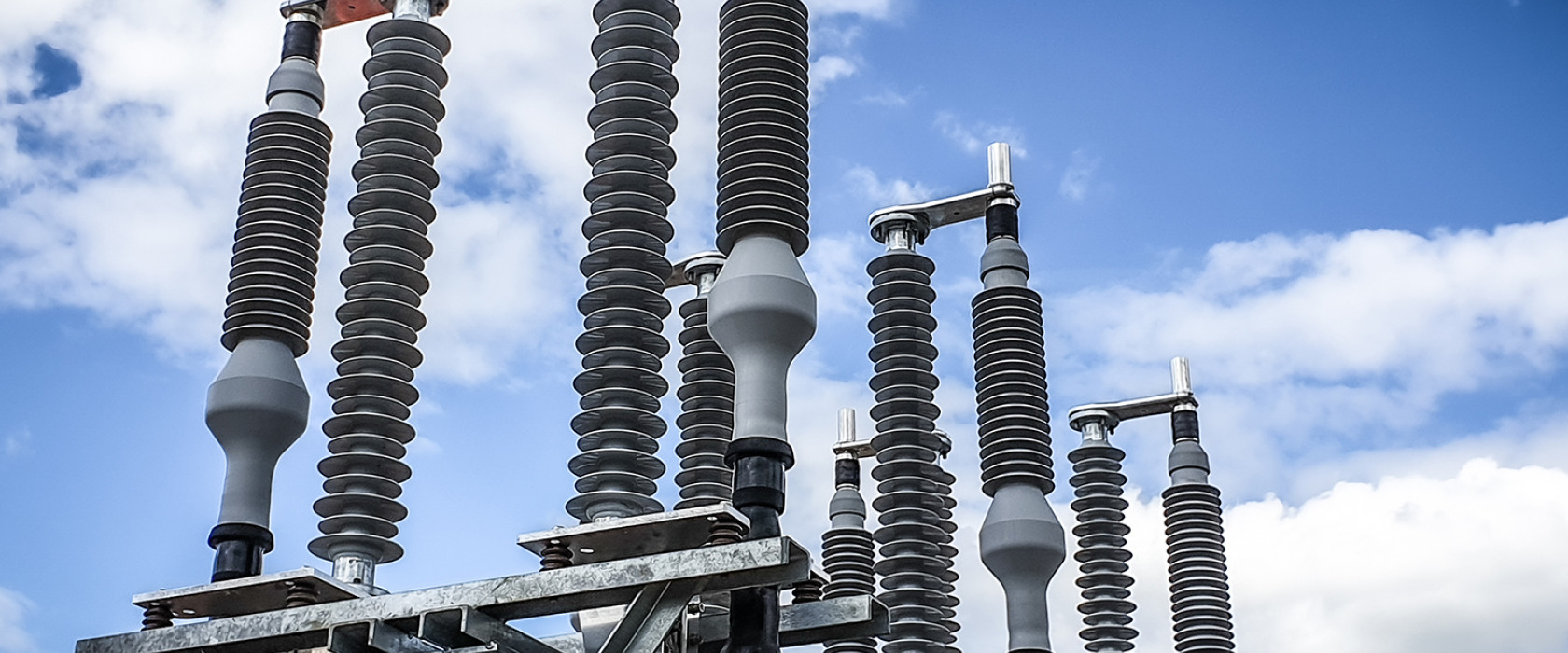

HV cable sealing end general arrangement, structure detailed and construction fabrication drawings

HV cable routing and trench cross section design

Cable system rating, induced voltage, short circuit circuits, impedance calculations, thermo-mechanical forces calculations, and primary design and interlocking interface at both substation ends

Horizontal Direction Drill (HDD) design underneath the M1 motorway in close proximity to the Network Rail railway line

Acting as client CDM2015 Principal Designer Representative

TP137 Independent Cable Verification and Lead Contractor Design Approval Engineer roles

With the cables connecting from a National Grid substation to a Network Rail ATFS, the routes needed to be designed to meet both organisations’ codes, standards and programmes. The 1.6km and 1.1km cable routes crossed the M1 motorway to connect to the new outdoor sealing ends (ODSE) at the ATFS, so Highways England standards also had to be taken into consideration.

Our team worked closely with all three organisations, plus National Grid and National Rail’s substation and cable contractors and their supply chains from the outset. This resulted in the design of an innovative trenchless Horizontal Directional Drill (HDD) methodology and a 66kV type cable arrangement that met all the required standards. This methodology allowed the cable routes to cross the motorway without adverse effect on the road surface caused by settlement. The highly optimised cable design will also keep cable system losses to an absolute minimum throughout its lifecycle.

The live substation, railway and M1 motorway all posed health and safety risks that needed to be minimised through the designs. Our engineers developed an innovative method of terminating the cables at each cable sealing end, this reduced both the amount of time spent working at height and the use of large temporary works scaffolding structures in close proximity to these live elements.

The methodology designed by our engineers consists of securely supporting the cables in a cradle at ground level, allowing all jointing works to occur without the need for expensive scaffolding. The cable and cable sealing end is then crane lifted in to place and fixed to the cable sealing end support structure. This ensures a safer construction environment, reduces installation costs through minimising the temporary works and equipment required, as well as expediting the construction programme.

With the cable route passing through a narrow corridor between the M1 motorway and the railway line, space for the cabling was highly constrained. Our engineers also had to work within the confines of the existing 400kV substation at cable origination, as well as considering existing underground obstacles, such as live HV cables, whilst designing the cable route.

Having a consistent and highly specialised team working on this project has allowed us to build a thorough understanding of the brief, design requirements and site challenges. This resulted in the design of a route that mitigated all obstacles, ensuring they were not de-rated and did not cross any environmentally sensitive areas located along the route, such as the water ditches. Redesign time and risk were both minimised along with programme delays and project costs.

The new connecting 25kV cable at Sundon will help futureproof the load capacity for the Midland Mainline Electrification. Our team’s innovative cable installation and termination methodologies ensured minimum disruption to road and rail traffic on the live routes that run next to and across the cable route. Helping minimise risk plus delivering programme and cost savings, the new cable route will provide a robust connection that will ultimately deliver a more efficient rail service.

European network, local expertise.